The return on investment for any maintenance organization is derived from a system’s availability. Availability is a function of a system’s mean time before failure (MTBF) and the mean time to repair (MTTR) a system once it has failed:

![]()

The MTTR translates directly into opportunity costs from the loss of availability. The longer it takes to repair a system the higher the maintenance costs inclusive of increased personnel to deal with failure frequencies and routine maintenance schedules.

Critical

to lowering MTTR is the competency level of the maintenance

crew and the efficacy of their tools. If an organization has

inherently high attrition rates, such as  a

voluntary military, the competency levels of their maintainers

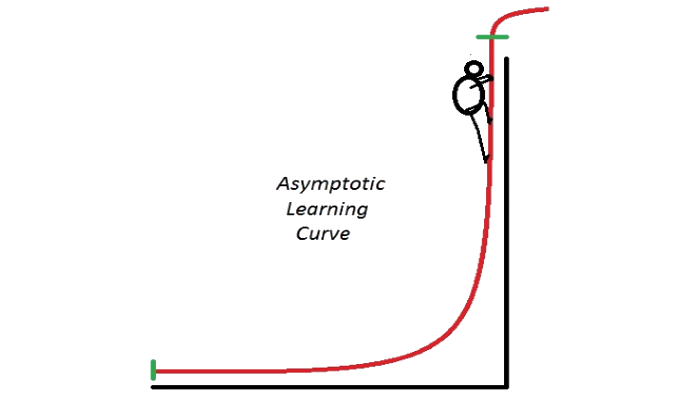

can vary widely. Learning curves are traditionally difficult

when dealing with complex systems. The time and effort to

learn a system are additional costs to the maintenance effort.

a

voluntary military, the competency levels of their maintainers

can vary widely. Learning curves are traditionally difficult

when dealing with complex systems. The time and effort to

learn a system are additional costs to the maintenance effort.

An

ideal solution to improve competency levels are to build tools

that can improve learning

asymptotically. Complex systems are difficult to comprehend

because of the enormous amounts of information necessary to

work with such systems. Human memory is inherently problematic

and information overload is a cognitive impediment, without

information processing tools dealing with information overload

is impossible!

learning

asymptotically. Complex systems are difficult to comprehend

because of the enormous amounts of information necessary to

work with such systems. Human memory is inherently problematic

and information overload is a cognitive impediment, without

information processing tools dealing with information overload

is impossible!

By transforming schematic diagrams into information that can be managed by information technology tools we can manage information overload. Tools, such as those produced by Atlas Dynamics, turn non-interactive diagrams into indexable information that build information relationships that allow for intuitive human interaction to work with very complex systems, thereby lessening MTTR by improving competency levels by not depending on human memory to articulate a systems intricate details of interconnectivity.

For this reason a Interactive Electronic Wiring Diagram (IEWD) tool is essential in a maintenance team's arsenal of tools. An ideal IEWD should have the following features:

A big picture perspective or view of the entire system, be it electrical, pneumatic or hydraulic circuits.

Fast searches of systems, subsystems, components, plugs, signals, powers and grounds that can be color traced entirely from beginning to end of a circuit across multiple diagrams.

Every circuit is defined as a generic type such as a ground, power or signal that allows for quick identification through colorization of all circuits on a diagram.

All auxiliary data is accessible from one interface, this can be images, animations, simulations, descriptive theories. This allows for maintainers to quickly identify the physical orientation of any diagram to the system that is being tested.

It must interface to other applications and freely exchange data between applications, such as IETMs.

Allows for the ability to easily share marked up drawings and/or share access to the tool itself that accelerates collaborative efforts.

An IEWD should have diagrams with components differentiated by color. (Cognitive studies have demonstrated that colorization of a diagram allows the human eye to quickly differentiate details of a diagram.)

With the benefit of all these features of an IEWD and any maintenance team will have improved performance that translates into drastically reduced MTTR. The improved MTTR performance can be as high as five to ten times because of the tool’s information accessibility, physical orientation cues, colorization of complex diagrams and cross diagram tracing abilities.